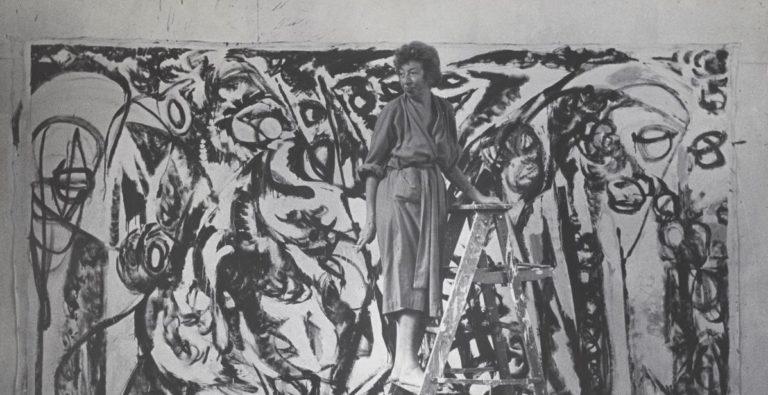

Most of the work I do is customer led, they pick the colours and I weave them. But what I loved about Alice’s process (Timothy Everest designer Alice) is that she does it proper old school with a storyboard and images. So for me as a designer, that was brilliant because I got to see the board with these amazing Lee Krasner paintings. That triggers these little lightbulb moments; I can try certain techniques and use certain yarns. Then we had a decent process back and forth until we got to the end result that everybody loved, and it was the “right” cloth. To me, that was lovely to see and be a part of that process.

It’s gratifying when you get that right relationship with a customer. A lot of the early ideas are mapped out by me on a CAD system which is very flat; it doesn’t look like the finished fabric at all. So while I can see it in my head, it takes a lot of faith and trust from the client. It’s a very visual and tactile adventure. Alice and Timothy Everest got that; but there’s not that many people who seem to work that way.

The process of weaving is so special. There’s lot going on. You have to pedal and nothing will move on the loom until you move your feet. I feel everything through my feet. I can tell when the paraffin lubricant is starting to evaporate; there’s this fractionally different felling in your feet as it starts to stiffen.

You’re watching the shuttle going back and forth, and you’re watching to make sure the yarn isn’t running out; you might have four different colours on different shuttles going at the same time, so you have to remember the pattern because you’ll need to stop it at the right fraction of a second to get it exactly right. It’s your concentration that gets tired before anything else.

It’s a lovely connection between eyes, hands, feet and machine.”